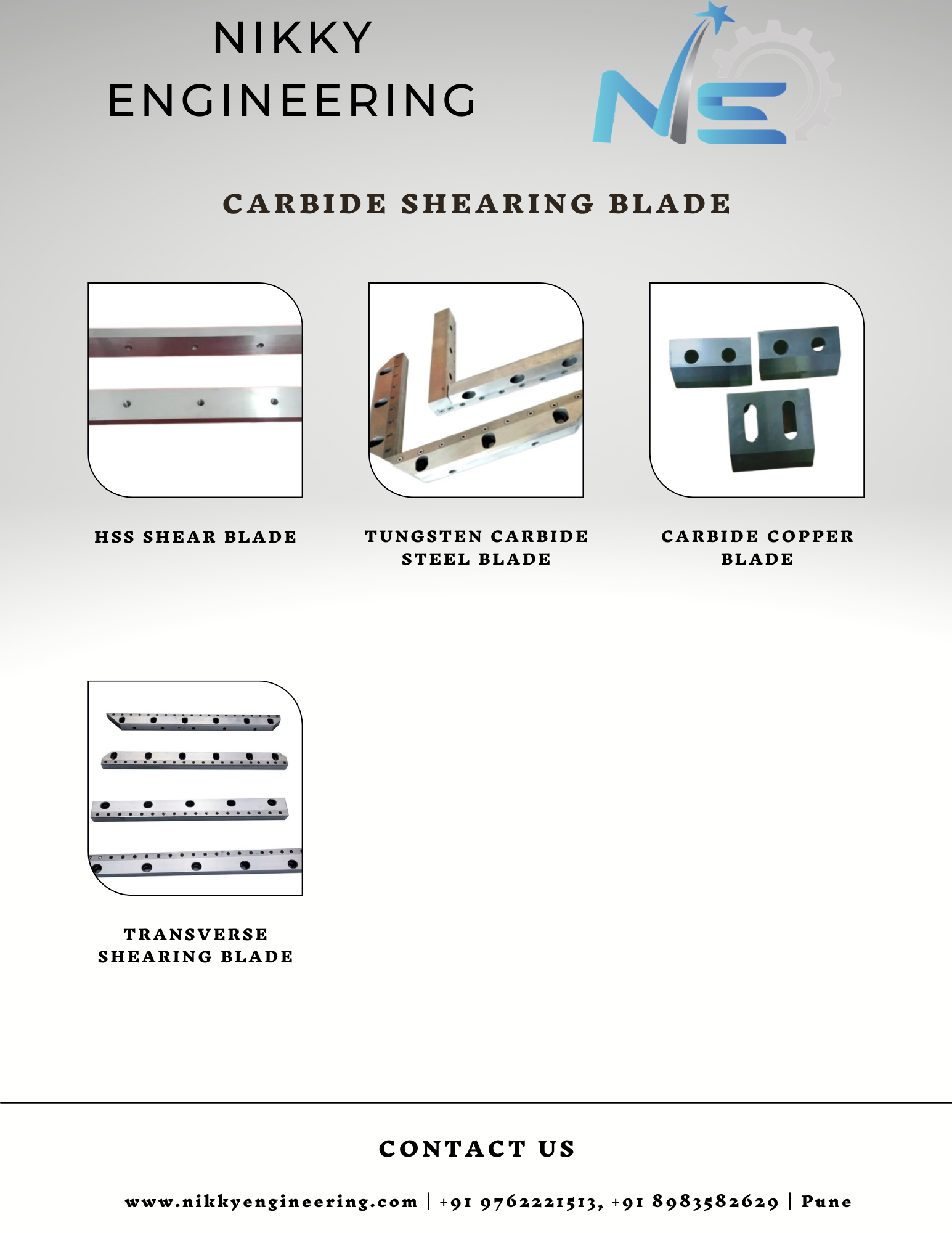

Shearing Blade Manufacturers in Pune India

Nikky Engineers are Shearing blade manufacturers in Pune India. Shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; if the cutting blades are curved then they are shearing-type operations.

Our clients can avail us of an exclusive range of Cutting Knives that are designed and devolved as per set industrial trends. We make use of the finest quality steel that is sourced in best of the form from trusted vendors. The production process is carried out under the strict quality control of our professionals and is put through thorough testing before making the final dispatch. We ensure the safe and timely dispatch of our products in large volumes.

All of our shear blades are crafted from the highest-quality alloys using close tolerance quality control standards. Our shear blades provide optimum performance and extended blade life, meaning that you receive more tons per edge while reducing downtime due to blade changes. Extended blade life combined with less downtime leads to a more productive and profitable production shearing operation.

Our blades are available in single-edge, two-edge, four-edge, and bowtie configurations. Each of these configurations is available in different alloy grades to suit your individual needs. All of our shear blades are thru-hardened to ensure consistent hardness; our in-house hardening and tempering furnace can handle shear blades up to 16 feet in length.

We offer the following shear blade grades to cover the most shearing applications possible:

- MARK I – Premium grade High Carbon/High Chrome tool steels, providing maximum life between regrinds when cutting mild steel up to .250” thick on mechanical shears. This grade is also ideal for shearing mild steel up to .375” thick on hydraulic shears, due to the lack of impact and slower cutting action.

- MARK II – Premium grade modified alloy tool steels, providing a maximum number of cuts before dulling when cutting mild steel grades up to 1” thick. These alloys have a high degree of toughness, combined with excellent shock resistance, making them equally suitable for shearing high tensile, heavy cross-section steels as well.

- MARK III – Premium grade alloy tool steels for unique situations, such as hot work type applications, where elevated temperatures would have an adverse effect on other alloys. Our technical staff can provide application assistance for these alloys in order to determine the correct alloy and hardness range.

Features:

- High Efficiency

- Durable

- High performance