CRGO Lamination machine accessories Manufacturers

We are CRGO Lamination machine accessories manufacturers in India. CRGO (Cold Rolled Grain Oriented) lamination machines are used to manufacture transformer cores. These machines require various accessories to operate efficiently and effectively. Some of the most commonly used CRGO lamination machine accessories include:

- Slitting lines: Slitting lines are used to cut CRGO coils into narrow strips that are used to manufacture transformer cores. These machines typically include decoilers, slitters, and recoilers.

- Cut-to-length lines: Cut-to-length lines are used to cut CRGO coils into specific lengths that are required for transformer core manufacturing. These machines typically include decoilers, straighteners, and shears.

- Notching machines: Notching machines are used to create the required notches in the CRGO strips or laminations. These notches are required to accommodate the winding wires of the transformer.

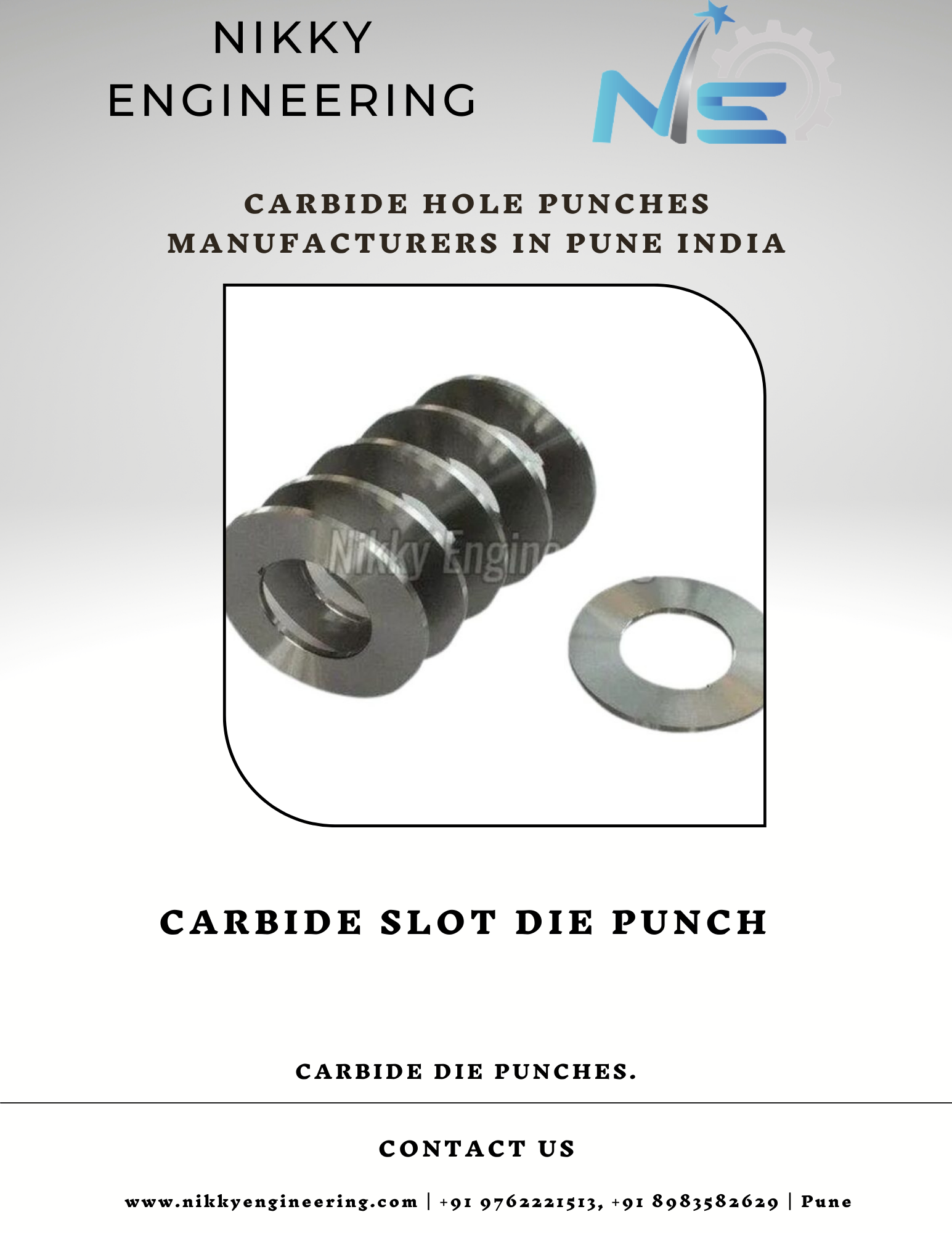

- Punching machines: Punching machines are used to create holes in the CRGO laminations for mounting purposes.

- Deburring machines: Deburring machines are used to remove sharp edges from the CRGO laminations. This is important to ensure that the laminations do not damage the winding wires during the transformer assembly process.

- Stacking machines: Stacking machines are used to stack the CRGO laminations together in a specific sequence to create the transformer core.

- Welding machines: Welding machines are used to weld the CRGO laminations together to create a complete transformer core.

- Insulating materials: Insulating materials are used to insulate the transformer core and prevent eddy current losses.

Overall, the accessories used in CRGO lamination machines play a critical role in ensuring the efficient and effective manufacturing of transformer cores.

Benefits

The use of CRGO (Cold Rolled Grain Oriented) lamination machine accessories offers several benefits to manufacturers of transformer cores. Some of these benefits include:

- Improved Efficiency: CRGO lamination machine accessories can help improve the efficiency of the transformer core manufacturing process by reducing the time and effort required to prepare and process the CRGO coils.

- Improved Precision: Accessories like slitters, notching machines, and punching machines can help improve the precision of the manufacturing process by ensuring that the CRGO strips and laminations are cut, notched, and punched accurately to the required dimensions.

- Reduced Material Waste: Accessories like slitters, edge trimmers, and scrap winders can help reduce material waste by minimizing the amount of excess material generated during the manufacturing process.

- Improved Safety: CRGO lamination machine accessories can help improve safety in the workplace by reducing the need for manual handling of heavy CRGO coils and reducing the risk of injury from sharp edges on the CRGO laminations.

- Higher Product Quality: The use of CRGO lamination machine accessories can help ensure that the transformer cores produced meet the required quality standards by improving the accuracy and precision of the manufacturing process.

- Increased Flexibility: With the use of various accessories, CRGO lamination machines can be adapted for different types of transformer cores, thus providing increased flexibility for manufacturers to produce a wide range of transformer cores.

Overall, the use of CRGO lamination machine accessories can help improve the efficiency, precision, safety, and quality of the transformer core manufacturing process, while also reducing material waste and providing greater flexibility for manufacturers.

Applications

CRGO (Cold Rolled Grain Oriented) lamination machine accessories have a wide range of applications in the manufacturing of transformer cores. Some of the most common applications of CRGO lamination machine accessories include:

- Power Transformers: CRGO lamination machine accessories are commonly used to manufacture transformer cores for power transformers used in the power generation, transmission, and distribution industry.

- Distribution Transformers: CRGO lamination machine accessories are used to manufacture transformer cores for distribution transformers used in the distribution of electricity to residential, commercial, and industrial customers.

- Instrument Transformers: CRGO lamination machine accessories are used to manufacture transformer cores for instrument transformers used for measuring and monitoring electrical parameters such as voltage, current, and frequency.

- Reactors: CRGO lamination machine accessories are used to manufacture transformer cores for reactors used in various applications such as inductive heating, electrical arc furnaces, and high-power motor drives.

- Audio Transformers: CRGO lamination machine accessories are used to manufacture transformer cores for audio transformers used in audio equipment such as amplifiers, mixers, and speakers.

- Communication Transformers: CRGO lamination machine accessories are used to manufacture transformer cores for communication transformers used in various applications such as radio frequency amplifiers, signal isolation, and impedance matching.

- Lighting Transformers: CRGO lamination machine accessories are used to manufacture transformer cores for lighting transformers used in various lighting applications such as streetlights, fluorescent lights, and LED lights.

Overall, CRGO lamination machine accessories are essential components in the manufacturing of transformer cores used in a wide range of industries and applications.