Carbide Shear Blade Manufacturers

We are Carbide shear blades manufacturers in India. Carbide shear blades are cutting tools made from tungsten carbide, a hard and durable material. They are used to cut a wide range of materials such as paper, plastic, rubber, and metal. Carbide shear blades have several advantages over other types of blades, including longer cutting life, greater accuracy, and improved cutting performance.

One of the primary benefits of carbide shear blades is their durability. Carbide is a hard and wear-resistant material that can withstand the high stresses and temperatures that occur during cutting. This means that carbide blades can last much longer than other types of blades, reducing the need for frequent blade replacements and maintenance.

Carbide shear blades also provide greater cutting accuracy than other types of blades. They have a high degree of dimensional stability, which means they are less likely to warp or distort during use. This makes them ideal for cutting materials that require precise cuts and shapes.

Another advantage of carbide shear blades is their improved cutting performance. Carbide blades can cut through tough materials with ease, thanks to their superior hardness and toughness. This can result in faster cutting speeds, lower operating costs, and increased productivity.

Carbide shear blades are an excellent choice for cutting a wide range of materials. They offer superior durability, cutting accuracy, and performance, making them a popular choice for industrial and manufacturing applications.

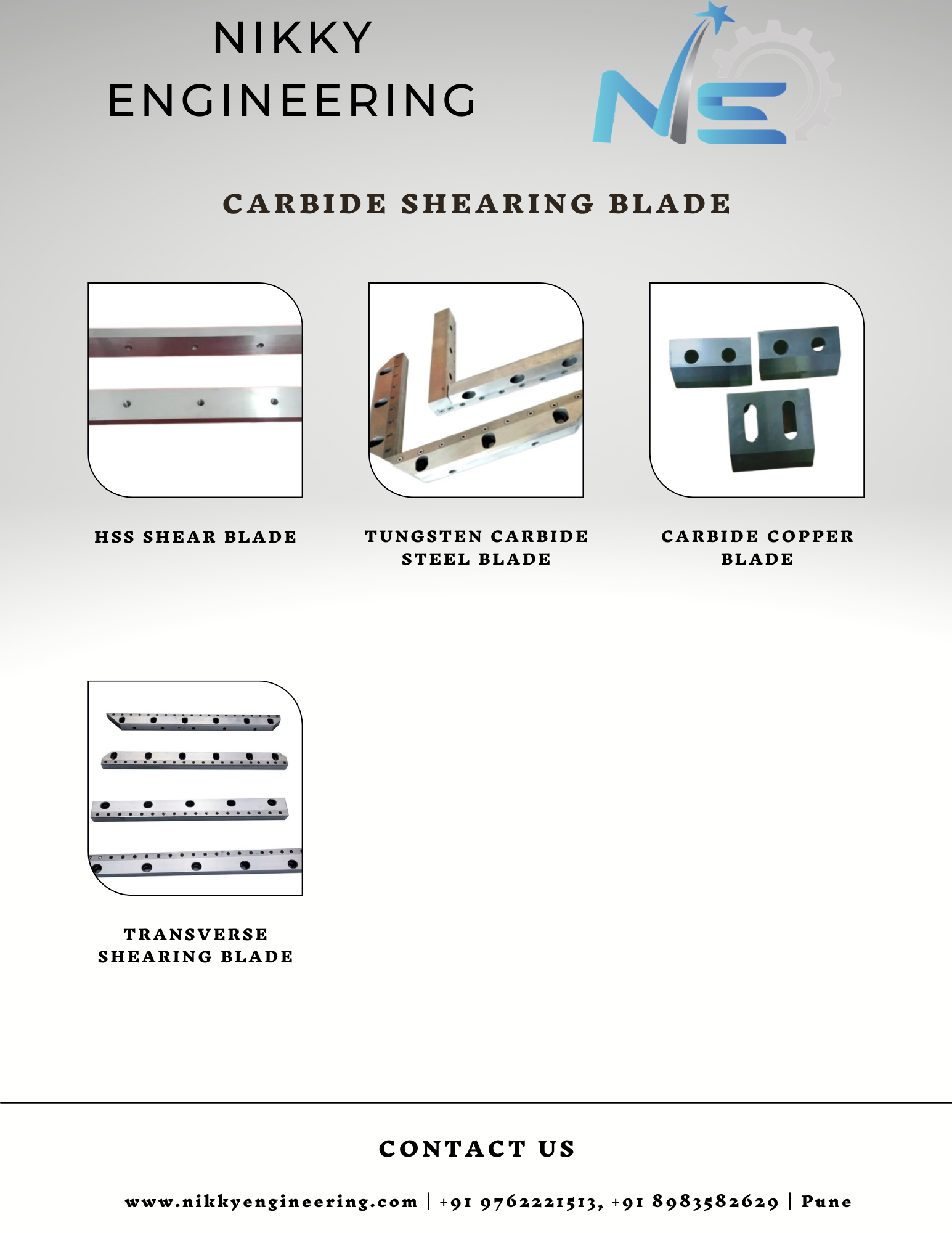

Types

There are several types of carbide shear blades available, each with unique properties that make them suitable for different cutting applications. Here are some common types of carbide shear blades:

- Solid Carbide Blades – These blades are made from a solid piece of carbide and are known for their high strength and durability. They are often used in heavy-duty cutting applications, such as in the automotive and aerospace industries.

- Tipped Carbide Blades – Tipped carbide blades have a steel body with carbide inserts attached to the cutting edge. They offer a good balance of strength, durability, and affordability, making them a popular choice for cutting a variety of materials.

- Carbide Circular Blades – These blades are circular and are used for cutting materials such as paper, cardboard, and textiles. They are known for their accuracy and precision and can produce clean, smooth cuts.

- Carbide Slitting Blades – Slitting blades are used for cutting thin materials, such as paper and film. Carbide slitting blades are ideal for this application because they can make precise cuts without causing the material to deform or warp.

- Carbide Guillotine Blades – Guillotine blades are used for cutting large sheets of materials, such as metal and plastic. Carbide guillotine blades are highly durable and can withstand the high stresses and pressures that occur during this type of cutting.

These are just a few of the types of carbide shear blades available. The right blade for your application will depend on the material being cut, the required precision and accuracy, and other factors.

Benefits of carbide shear blades

Carbide shear blades offer several benefits over other types of blades, including:

- High Durability: Carbide is an extremely hard and durable material, making carbide shear blades resistant to wear and able to withstand high stresses and temperatures during cutting. This results in longer blade life and reduced maintenance costs.

- Increased Cutting Performance: Carbide shear blades are designed to provide excellent cutting performance, with the ability to cut through tough materials quickly and efficiently. This results in faster cutting speeds, higher productivity, and lower operating costs.

- Improved Cutting Accuracy: Carbide shear blades are known for their dimensional stability and precision, which allows for accurate and clean cuts. This is particularly important in industries where precision and accuracy are critical, such as aerospace, automotive, and electronics.

- Versatility: Carbide shear blades can be used to cut a wide range of materials, including metal, plastic, rubber, and wood. This makes them a versatile cutting tool for many industries and applications.

- Lower Maintenance Costs: Due to their high durability and long cutting life, carbide shear blades require less frequent maintenance and replacement compared to other types of blades. This results in lower operating costs and increased productivity.

Applications

Carbide shear blades are used in a wide range of cutting applications across many different industries. Some common applications of carbide shear blades include:

- Metal Cutting: Carbide shear blades are ideal for cutting a variety of metals, including steel, aluminum, and copper. They are commonly used in the automotive, aerospace, and manufacturing industries.

- Plastic Cutting: Carbide shear blades can cut through a wide range of plastic materials, including PVC, polycarbonate, and acrylic. They are used in industries such as packaging, electronics, and consumer goods.

- Paper and Cardboard Cutting: Carbide shear blades are used to cut paper and cardboard in the printing, publishing, and packaging industries. They offer precision cutting and a longer lifespan compared to traditional blades.

- Rubber Cutting: Carbide shear blades are ideal for cutting rubber materials, including tires, hoses, and seals. They offer high cutting performance and accuracy.

- Wood Cutting: Carbide shear blades are used in the woodworking industry for cutting hardwoods and engineered woods. They offer precise cuts and improved performance compared to traditional blades.

- Textile Cutting: Carbide shear blades are used in the textile industry for cutting fabrics, leather, and other materials. They provide a clean cut without damaging the material.

In summary, carbide shear blades are versatile cutting tools that can be used in many different industries and applications. Their durability, cutting performance, and accuracy make them an excellent choice for cutting a wide range of materials.

If you have any requirements then contact us.