CRGO Metal cutting tools manufacturers and Suppliers

We are CRGO metal cutting tools manufacturers in India. CRGO (Cold Rolled Grain Oriented) metal cutting tools require specialized cutting tools due to the nature of the material. CRGO steel is a highly specialized magnetic steel alloy used in the construction of transformers, generators, and other electrical equipment.

The cutting tools used for CRGO steel must be made of high-speed steel (HSS) or carbide and must have the correct geometry and edge preparation to ensure a clean cut with minimal burrs or surface damage. The cutting speed and feed rates must also be carefully controlled to avoid overheating and deformation of the material.

Some commonly used cutting tools for CRGO steel include saw blades, milling cutters, and drills. These tools must be specifically designed for cutting CRGO steel, as the material has unique properties that can cause wear and tear on ordinary cutting tools.

Overall, it is important to choose the right cutting tools and use proper cutting parameters when working with CRGO steel to ensure high-quality cuts and minimize the risk of damage to the material.

Types

There are several types of cutting tools that can be used for cutting CRGO (Cold Rolled Grain Oriented) metal, including:

- Circular saw blades: These are circular-shaped blades with teeth around the edge that can be used for cutting CRGO sheets and plates.

- Carbide end mills: These are cutting tools that are used for milling operations, and they are designed to remove material from the surface of CRGO steel. They are made of carbide, which is a hard and durable material that can withstand the high temperatures generated during the cutting process.

- Drills: Drills are cutting tools that are used for making holes in CRGO steel. They come in different sizes and shapes, and they can be made of high-speed steel or carbide.

- Shearing blades: These are flat, rectangular-shaped blades that can be used for cutting CRGO sheets and plates. They work by applying a shearing force to the material, which causes it to fracture along a defined cutting line.

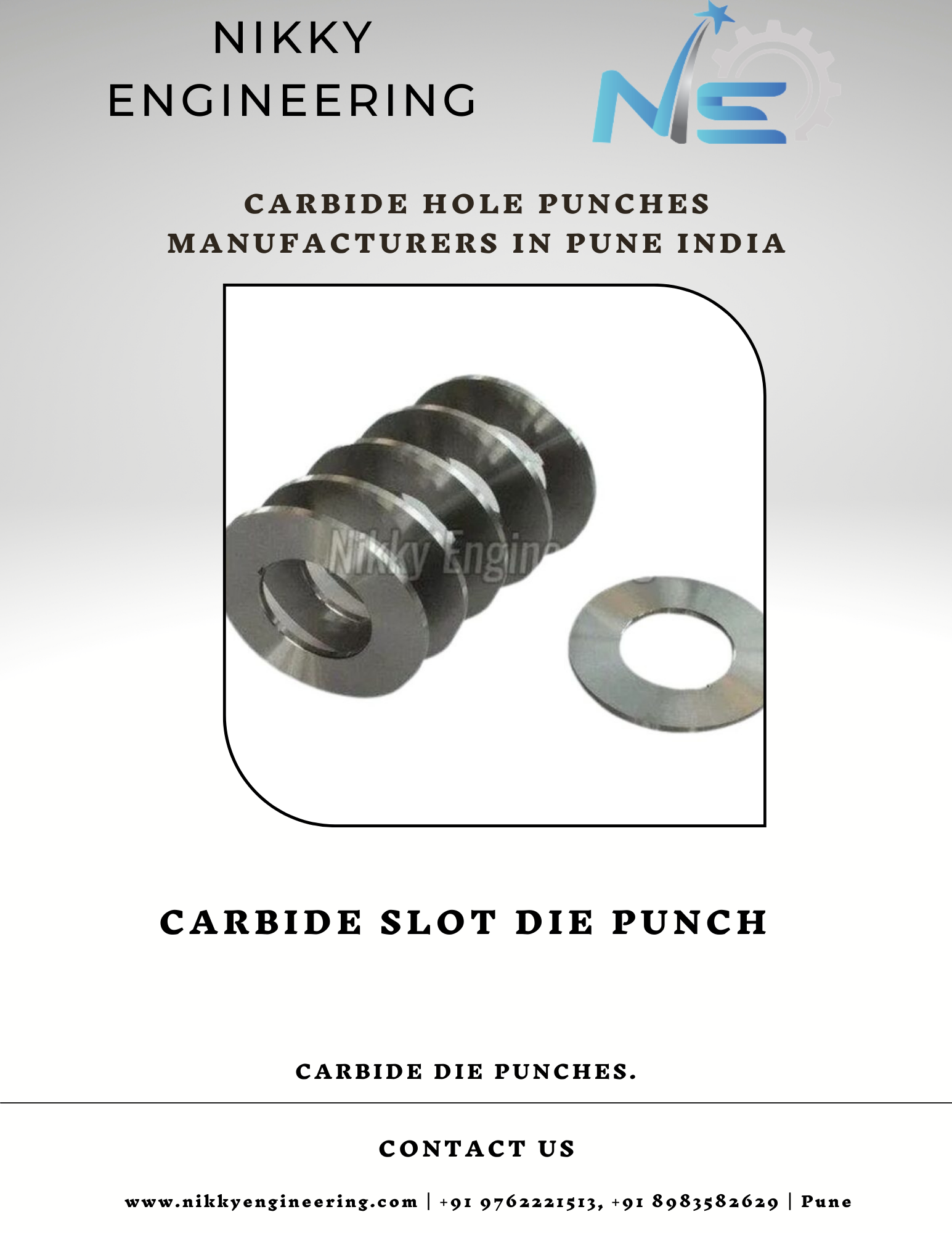

- Punches: Punches are tools that are used for creating holes or indentations in CRGO steel. They come in different shapes and sizes, and they can be used for a variety of applications.

Overall, the choice of cutting tool will depend on the specific application, the thickness of the material being cut, and the desired quality of the cut. It is important to choose the right cutting tool and use proper cutting parameters to ensure high-quality cuts and minimize the risk of damage to the material.

Benefits

The use of specialized cutting tools for CRGO (Cold Rolled Grain Oriented) metal offers several benefits, including:

- Improved cutting performance: CRGO steel has unique magnetic properties that make it more difficult to cut than other types of steel. By using specialized cutting tools that are designed specifically for cutting CRGO steel, you can achieve better cutting performance, with fewer burrs, and a smoother surface finish.

- Longer tool life: Cutting tools that are not designed for cutting CRGO steel can wear out quickly due to the material’s high silicon content, which can cause tool wear and chipping. Using specialized cutting tools made from materials such as carbide or high-speed steel can significantly increase tool life, reducing the need for frequent tool replacements.

- Reduced downtime: By using specialized cutting tools that are designed for cutting CRGO steel, you can reduce the risk of tool breakage and other issues that can cause production downtime. This can help to improve overall productivity and efficiency.

- Cost-effective: Although specialized cutting tools for CRGO steel may have a higher initial cost than standard cutting tools, their longer tool life and improved cutting performance can make them more cost-effective in the long run.

Overall, the use of specialized cutting tools for CRGO steel can help to improve cutting performance, increase tool life, reduce downtime, and offer a more cost-effective solution for cutting this challenging material.

Application

CRGO (Cold Rolled Grain Oriented) metal cutting tools are used in various applications where the precise and efficient cutting of CRGO steel is required. Some common applications of CRGO metal cutting tools include:

- Transformer manufacturing: CRGO steel is widely used in the construction of transformers, which are essential components of electrical power systems. CRGO steel sheets must be precisely cut to specific dimensions to ensure optimal performance of the transformer. Cutting tools such as saw blades, shearing blades, and drills are commonly used in transformer manufacturing.

- Motor manufacturing: CRGO steel is also used in the construction of electric motors, such as those used in industrial machinery, appliances, and automotive applications. Cutting tools such as end mills and drills are used to create the necessary holes and shapes in CRGO steel to make motor components.

- Electrical appliance manufacturing: CRGO steel is used in the construction of various electrical appliances, including refrigerators, washing machines, and air conditioners. Cutting tools such as shearing blades and punches are commonly used to cut and shape CRGO steel sheets for these applications.

- Renewable energy applications: CRGO steel is also used in the construction of generators and other components in wind turbines and solar power systems. Cutting tools such as saw blades and drills are used to create precise cuts in CRGO steel sheets for these applications.

Overall, CRGO metal cutting tools are used in a wide range of applications where precise and efficient cutting of CRGO steel is essential for the performance and durability of electrical equipment and renewable energy systems.