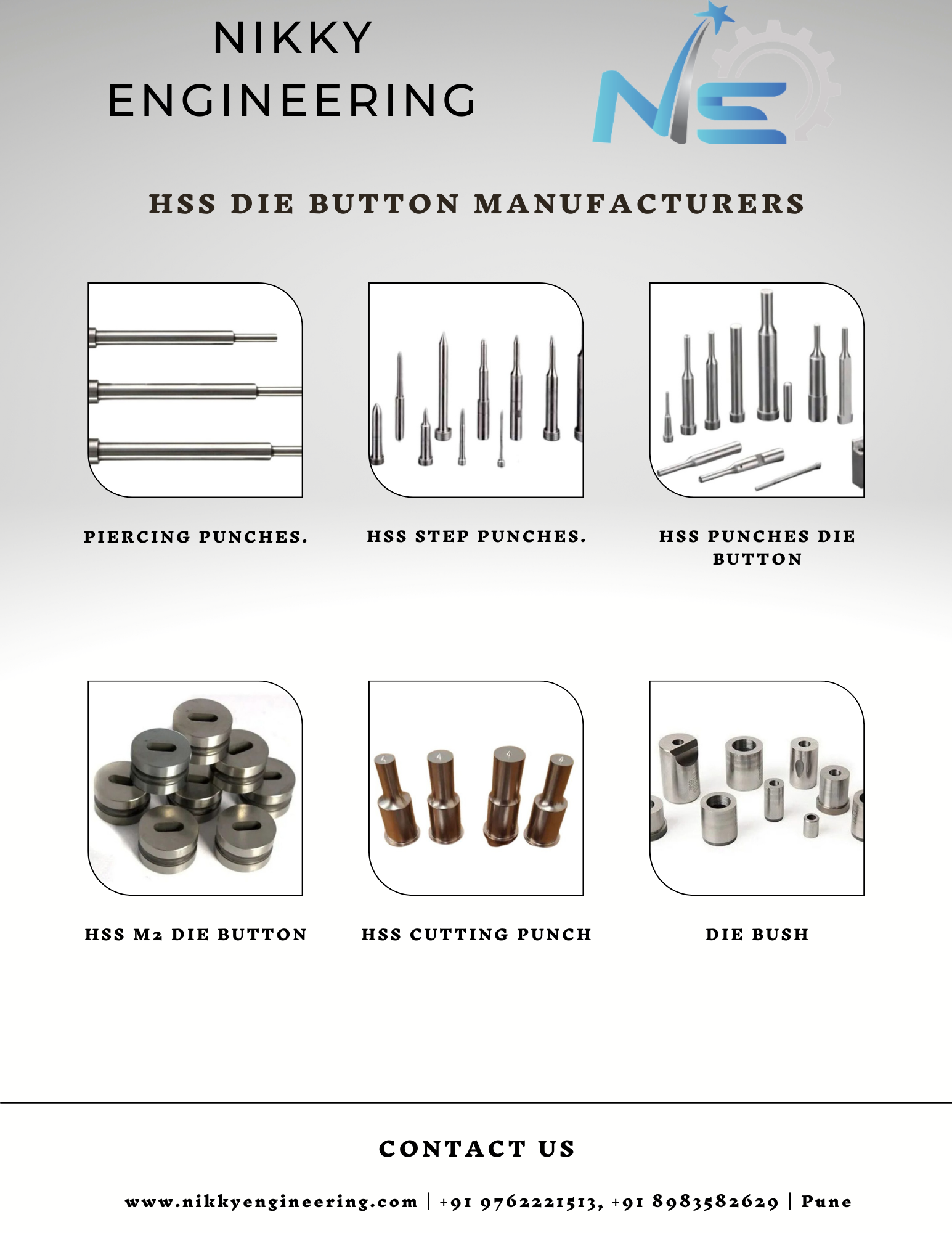

HSS Step Punches Manufacturers

We are HSS step punches manufacturers in India. HSS (High-Speed Steel) step punches are specialized cutting tools used for punching holes of different diameters in sheet metal and other materials. These punches are made of high-speed steel, which allows them to maintain their sharpness and withstand high temperatures generated during the punching process.

Step punches have a stepped design that allows them to create holes of various diameters in a single operation. They typically consist of multiple cutting edges arranged at different heights on the punch, with each edge corresponding to a specific hole diameter. As the punch is pressed into the material, each cutting edge removes a layer of material to create the desired hole size.

Types of HSS step punches

There are several types of HSS step punches, each designed for specific applications. Here are some of the most common types:

- Standard step punches – These punches have a stepped design with two or more cutting edges that allow them to create holes of different sizes.

- Multi-level step punches – These punches have multiple steps, each with its own set of cutting edges, to create holes of varying depths and diameters in a single operation.

- Countersink step punches – These punches are designed to create a countersunk hole, where the top of the hole is wider than the bottom. They are commonly used in industries such as aerospace and defense, where flush-mounting of fasteners is required.

- Bullet-nose step punches – These punches have a pointed tip that allows them to create holes in tight spaces or at awkward angles.

- Custom step punches – These punches are designed to meet specific requirements, such as creating holes with non-standard diameters or shapes. They are typically made to order and can be customized to suit the customer’s needs.

Overall, the type of HSS step punch used depends on the specific application and the type of material being punched.

Benefits

There are several benefits of using HSS step punches in manufacturing and metalworking applications. Here are some of the key benefits:

- High-speed steel construction – HSS step punches are made of high-speed steel, which is a durable and hard material that can withstand high temperatures and maintain sharpness even under heavy use.

- Efficient and precise – Step punches can create holes of different sizes in a single operation, which saves time and increases efficiency. They can also create precise and accurate holes with clean edges, which is essential for many manufacturing applications.

- Versatile – Step punches can be used to punch holes in a variety of materials, including metals, plastics, and composites. They are also available in a range of sizes and configurations, making them suitable for a wide range of applications.

- Easy to use – HSS step punches can be used with both manual and automatic punching machines, and require minimal setup time. They are also easy to maintain and can be sharpened or replaced when necessary.

- Cost-effective – HSS step punches are a cost-effective alternative to other cutting tools, such as drills or end mills, for creating holes of different sizes. They also have a longer lifespan than many other cutting tools, which reduces the need for frequent replacement.

Overall, HSS step punches offer a range of benefits that make them an ideal choice for many manufacturing and metalworking applications.

Applications:

HSS step punches are used in a wide range of manufacturing and metalworking applications where precise and efficient hole punching is required. Here are some of the most common applications of HSS step punches:

- Automotive manufacturing – Step punches are commonly used in the automotive industry for creating holes in sheet metal for components such as brackets, supports, and frames.

- Aerospace manufacturing – The aerospace industry also uses step punches for creating holes in sheet metal for aircraft components such as fuselage skins, engine mounts, and brackets.

- Electronics manufacturing – Step punches are used in the electronics industry for creating holes in printed circuit boards (PCBs) for components such as resistors, capacitors, and connectors.

- Medical device manufacturing – Medical device manufacturers use step punches for creating holes in components such as implantable devices, surgical instruments, and medical equipment.

- Metal fabrication – Step punches are also commonly used in metal fabrication applications such as sheet metal work, metal stamping, and metal forming.

Overall, HSS step punches are versatile cutting tools that can be used in a wide range of applications where precise and efficient hole punching is required.