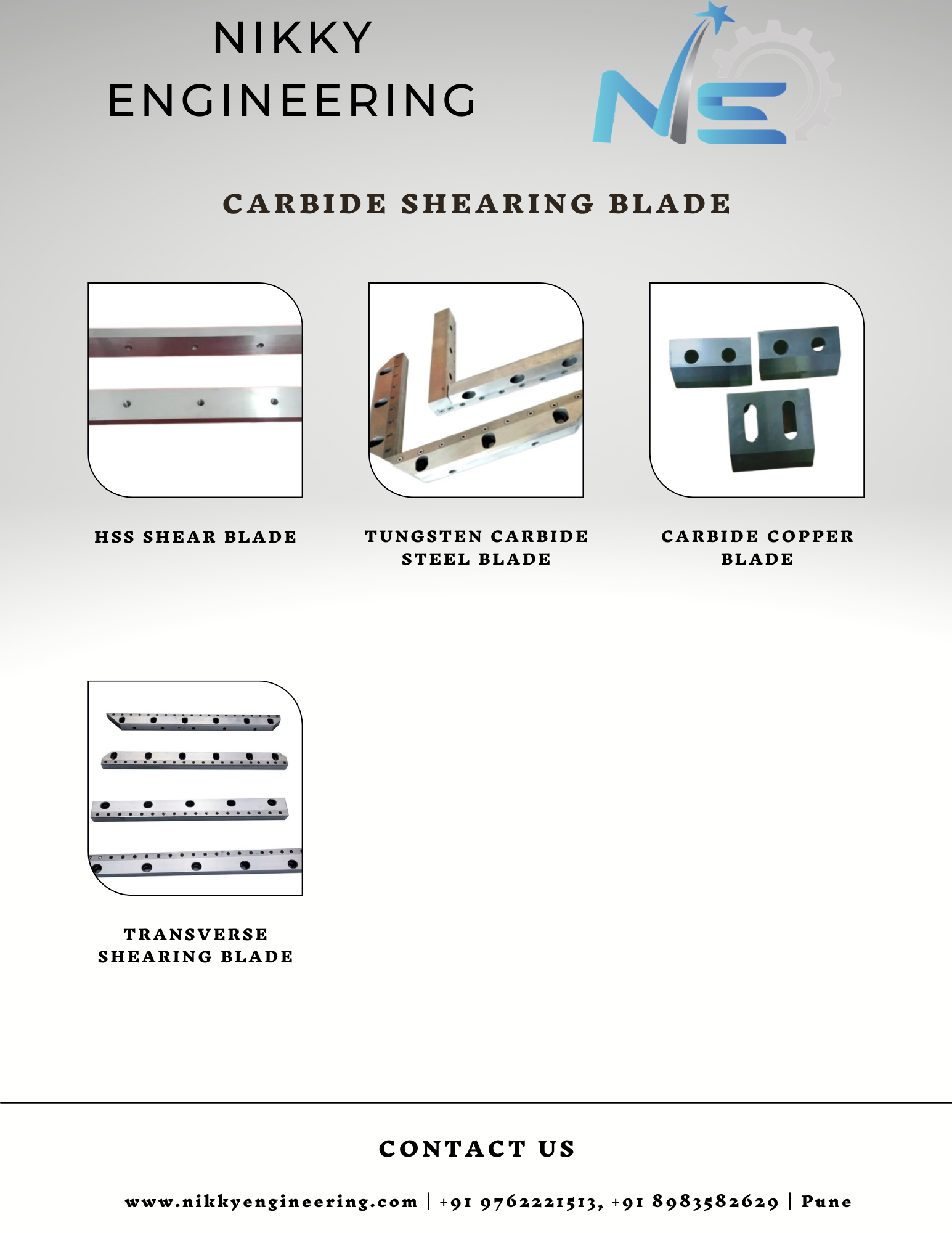

Scrap Shearing Blade Manufacturers

We are scrap shearing blade manufacturers in India. A scrap shearing blade is a tool used in metal recycling facilities to cut and shear various types of scrap metal. The blade is typically made of a high-strength steel material that can withstand the forces involved in cutting and shearing metal.

Scrap shearing blades can come in a variety of shapes and sizes, depending on the type of scrap metal being processed and the specific machinery being used. Some blades may have a serrated edge to provide additional grip and cutting power, while others may be smooth and sharp for a clean, precise cut.

These blades are an important component of the metal recycling process, as they allow for efficient and safe handling of scrap metal materials. Proper maintenance and sharpening of the blades are essential to ensure their continued effectiveness and longevity.

Types

There are several types of scrap shearing blades, each designed for specific purposes and applications. Some of the most common types include:

- Flat shear blades: These blades are typically used for shearing flat or sheet metal. They have a flat cutting edge and are often used in machines such as hydraulic guillotine shears.

- Rotary shear blades: These blades are designed for cutting and shearing thicker and tougher materials, such as steel bars and rods. They have a circular cutting edge and are often used in machines such as rotary shears.

- Guillotine shear blades: These blades are used in guillotine shearing machines, which are designed to cut large sheets of metal quickly and efficiently. Guillotine shear blades have a straight cutting edge and are typically used for cutting sheet metal, plate, and bar stock.

- Crocodile shear blades: These blades are used in crocodile shearing machines, which are designed to cut large metal objects such as pipes and beams. Crocodile shear blades have a curved cutting edge and are typically used for cutting thick and heavy materials.

- Alligator shear blades: These blades are used in alligator shearing machines, which are similar to crocodile shears but are designed for cutting smaller and thinner materials. Alligator shear blades have a straight cutting edge and are typically used for cutting sheet metal, wire, and other thin materials.

Overall, the type of scrap shearing blade used will depend on the specific application and the type of material being processed.

Benefits

The use of scrap shearing blades offers several benefits in the metal recycling industry, including:

- Efficient processing: Scrap shearing blades enable quick and efficient processing of large volumes of scrap metal. They can cut and shear metal materials into smaller, more manageable pieces, which can be melted down or further processed.

- Cost-effective: Scrap shearing blades are a cost-effective solution for metal recycling facilities, as they reduce the need for manual labor and can cut down on processing time.

- Safety: By using scrap shearing blades, metal recycling facilities can reduce the risk of workplace injuries and accidents. Blades are designed to cut and shear metal materials quickly and efficiently, minimizing the need for manual cutting and reducing the risk of operator error.

- Increased accuracy: Scrap shearing blades offer a high degree of accuracy and precision, ensuring that scrap metal materials are cut and sheared to the desired size and shape.

- Longevity: High-quality scrap shearing blades are designed to withstand the rigors of metal processing and can last for many years with proper maintenance and sharpening.

Overall, the use of scrap shearing blades can help metal recycling facilities to increase efficiency, reduce costs, and improve safety, while also producing high-quality scrap metal materials that can be further processed and used in a variety of applications.

Applications

Scrap shearing blades have many applications in the metal recycling industry, including:

- Automotive recycling: Scrap shearing blades are used to process scrap metal from vehicles, including engine blocks, transmissions, and other metal components.

- Demolition and construction waste recycling: Scrap shearing blades can be used to cut and shear metal materials from demolition and construction waste, including steel beams, pipes, and other metal structures.

- Electrical equipment recycling: Scrap shearing blades are used to process metal materials from old electrical equipment, such as motors, generators, and transformers.

- Manufacturing waste recycling: Scrap shearing blades can be used to process scrap metal generated during manufacturing processes, such as metal stamping, machining, and fabrication.

- General scrap metal recycling: Scrap shearing blades can be used to process a wide range of scrap metal materials, including copper, aluminum, brass, and stainless steel.

Overall, scrap shearing blades are a versatile tool used in a variety of metal recycling applications. They enable efficient and cost-effective processing of scrap metal materials, while also improving safety and accuracy in metal recycling facilities.

If you have any requirements then please contact us.