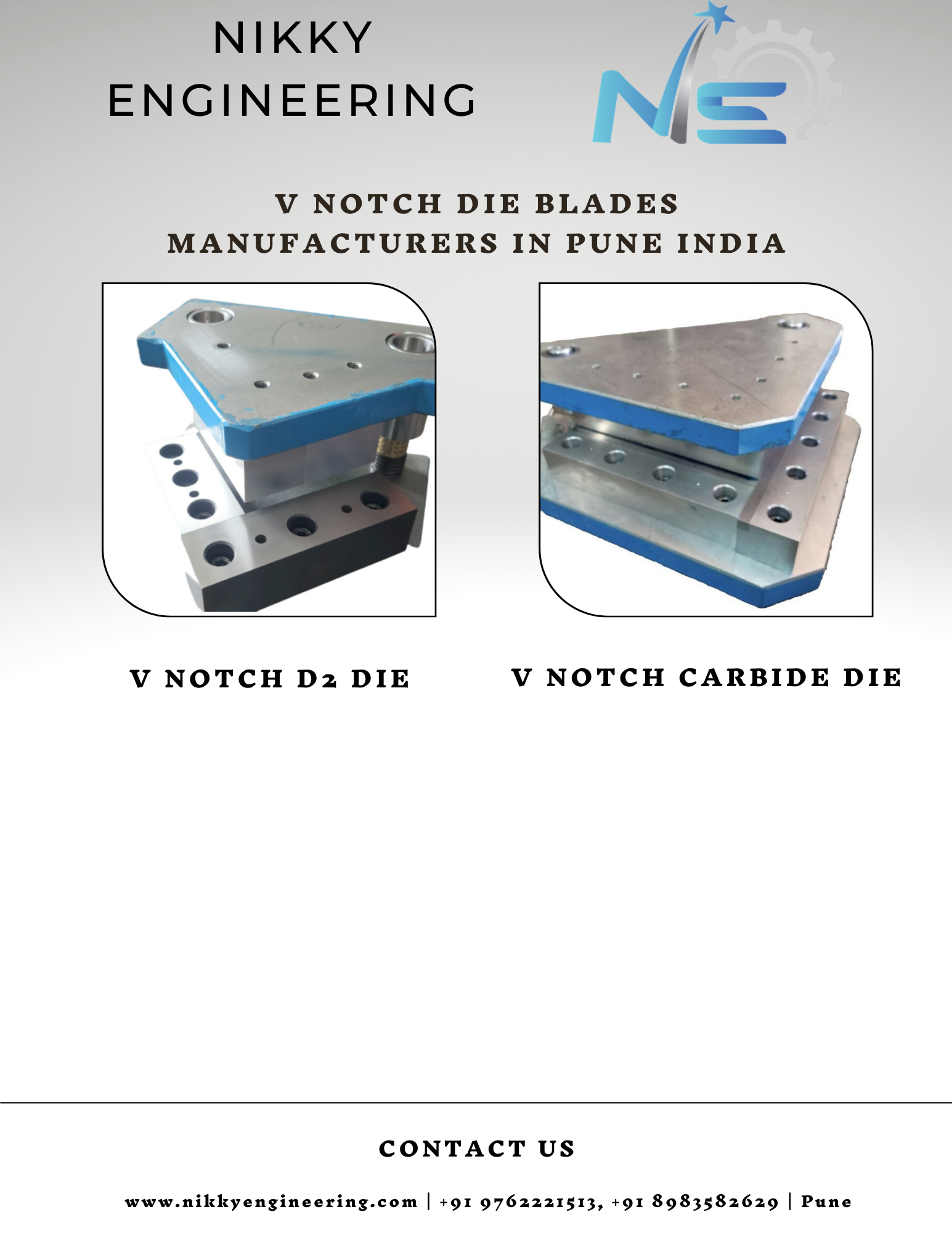

V Notch Die Blades Manufacturers

We are V –notch die blade manufacturers in India. A V-notch die blade is a cutting tool used in manufacturing processes to create V-shaped cuts in materials such as metal, plastic, or paper. It is typically made of high-speed steel or carbide and is designed to be used in a press or other cutting machine.

The V-notch die blade has a sharp, angled edge that is shaped like a V, with the sides of the V forming the cutting edges. When the material is fed through the machine and comes into contact with the blade, the V-notch blade cuts through the material, creating a clean, precise V-shaped cut.

Types

There are several types of V-notch die blades available for different cutting applications. Here are some of the most common types:

- Straight V-notch die blade: This is a basic V-notch die blade with straight edges, used for cutting straight V-shaped grooves in materials.

- Right-angle V-notch die blade: This blade has a V-shaped edge with a right angle at the bottom, allowing it to cut V-shaped grooves at a 90-degree angle.

- Acute-angle V-notch die blade: This blade has a sharper angle at the bottom of the V-shape, allowing it to cut narrower V-shaped grooves.

- Wide V-notch die blade: This blade has wider V-shaped edges, allowing it to cut wider grooves in materials.

- Dual V-notch die blade: This blade has two V-shaped edges, one on each side, allowing it to cut two grooves at once.

- Custom V-notch die blade: This is a specialized V-notch die blade that is designed to meet specific cutting requirements, such as cutting irregular or asymmetrical V-shaped grooves.

The choice of V-notch die blade depends on the specific application and the material being cut. It’s important to select the right type of blade for optimal cutting performance and to ensure a clean and precise cut.

Benefits

There are several benefits to using V-notch die blades for cutting applications. Here are some of the main advantages:

- Precision: V-notch die blades are designed to create precise cuts with clean, sharp edges. They can create V-shaped grooves with consistent depth and width, which is important for ensuring the quality and accuracy of finished products.

- Efficiency: V-notch die blades can cut quickly and efficiently, allowing for high-volume production with minimal downtime. They are especially useful in automated cutting processes, where speed and consistency are important.

- Versatility: V-notch die blades can be used to cut a wide range of materials, including metal, plastic, paper, and cardboard. They can create V-shaped grooves of varying sizes and shapes, making them useful for a variety of applications.

- Durability: V-notch die blades are typically made from high-quality materials, such as high-speed steel or carbide, which are designed to withstand the rigors of cutting. They can be sharpened or replaced as needed to maintain cutting performance.

- Cost-effective: V-notch die blades are a cost-effective cutting solution, especially for high-volume production. They require minimal maintenance and can be reused many times, making them a more economical option compared to other cutting methods.

Overall, the benefits of V-notch die blades make them a popular choice for many cutting applications in manufacturing and other industries.

Applications

V-notch die blades are commonly used in a wide range of cutting applications across many different industries. Here are some of the most common applications:

- Sheet metal fabrication: V-notch die blades are often used to cut V-shaped grooves in sheet metal, which can then be bent or folded into different shapes and structures.

- Plastic part manufacturing: V-notch die blades can be used to create grooves in plastic parts for assembly or other purposes.

- Paper and cardboard production: V-notch die blades can be used to create decorative or functional V-shaped cuts in paper or cardboard, such as for packaging or product displays.

- Woodworking: V-notch die blades can be used to create V-shaped grooves in wood for decorative purposes, such as in furniture or cabinetry.

- Textile manufacturing: V-notch die blades can be used to cut fabric into specific shapes or patterns, such as for clothing or upholstery.

- Automotive industry: V-notch die blades can be used to cut various automotive parts, such as gaskets, seals, and trim components.

Overall, the versatility of V-notch die blades makes them a valuable cutting tool for many different industries and applications. They are particularly useful for creating precise V-shaped cuts in a variety of materials, which can be used for a wide range of purposes.

If you have any requirements then contact us.